Medical isotopes production

Medical isotopes, or radionuclides, are radioactive materials used in nuclear medicine. Nuclear medicine specialists use them to diagnose (determine whether organs are functioning properly and to detect cancerous growths at an early stage) and treat (by irradiation with isotopes) various diseases, including cancer.

What are medical isotopes and how are they made?

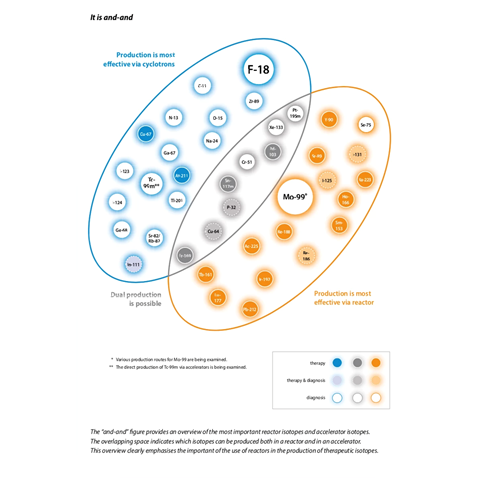

Can only reactors produce medical isotopes?

For certain isotopes, you have to add a particle to the atom to get the desired radioactive properties. This can only be done in a nuclear reactor.

For other isotopes, you have to reflect a particle from an atom to get the desired properties. This is possible only with a particle accelerator (cyclotron). Isotopes produced in cyclotrons have only diagnostic purposes and produce a smaller volume.

Both reactors and cyclotrons are needed.

Processing of the isotopes and their supply chain

The irradiation of raw materials in the reactor (or in a cyclotron) is only a small part of the production process of medical isotopes. A series of purification and process steps in various laboratories follows the irradiation. The extent to which reactors can play a role in the production of medical isotopes strongly depends on the proximity of parties who can quickly prepare and transport the irradiated materials to the hospitals. Sophisticated logistics are extremely important due to the short lifespan of isotopes.

The PALLAS-reactor can benefit from the complete infrastructure of the PALLAS Programme, allowing the whole process to be realised directly at the Energy & Health Campus in Petten.

Importance of the PALLAS-reactor in medical isotopes production

The Netherlands occupies a special position in Europe by supplying 70 per cent of European and 35 per cent of the world's demand for medical isotopes.

Not only is the Netherlands currently the largest producer of medical isotopes in the world, along with Australia (the OPAL reactor is only over 10 years old), it is also the only country that has the reactor and the molybdenum-processing facility on the same site. This offers many advantages, not least that radioactive materials do not need to be transported by road. As transportation times are non-existent, the efficiency of the entire production process is higher (less decay of molybdenum during the process), and this results in less waste.

Only a few (old) reactors worldwide account for the lion’s share of medical isotope production. In 15 years, 75 per cent of the reactors will need to be replaced.

The PALLAS-reactor ensures continuity of medical isotope production, which is vital for thousands of patients worldwide every day.

How can we help you?